Anderson Agri-forest Equipment Inc. Tel: 1-866-681-0550 E-mail: info@andersonagri-forest.com

A nderso n

nderso n

Francais

Francais

Rabaud

General characteristics

Semi-automatic peeler adaptable on Tractor 3-point linkage using PTO Driven Hydraulic Unit.

Peels wood of diameter 40 mm (1.6”) up to 250 mm (10”).

Wood forwarding speed can be adjusted: Output 60 up to 120 posts/hr.

Adjustment of the peeling quality by pressure of the two pinions on the wood.

Very efficient machine due to convex disc fitted with 6 adjustable blades.

Post is held at the entrance and at the exit of the machine with the V-positioned wheels.

Discharge blower for the chips with mobile spout at 360°. Ideal for discharging the chips into a trailer.

NEW: Automatic release of the driving rollers (option) See below.

Peels all sorts of round posts: chestnut, black-wood, oak…

Technical characteristics

Minimum post diameter ……………….………… 40 mm (1.6”)

Maximum post diameter .……………………….. 250 mm (10”)

Dimensions (L x W x H) ………………………...1.42 m x 2.39 m x 2.60 m (60” x 94” x 102.5”)

Weight …………………………………………….. 585 Kg (1287 lbs)

Disc speed ……………………………………….. 1,500 rpm

Number of blades ………………………………… 6

Drive PTO speed…………………………………. 540 rpm

PTO Power required ……………………………… 20 HP

Coupling Tractor 3-point linkage ………………… Category N°2 with removable pins

Discharge of chips By the top with the spout

Automatic release of the in-feed rollers by the use of an electronic sensor (laser) enabling the elimination of the standard pedal

PTO Driven Hydraulic Unit Pump

Delivers 30L/min.

Oil tank Capacity 40L

Delivered with oil

(Note: PTO Shaft not included).

General characteristics

Manual Peeler adaptable on Tractor 3-point linkage

Peels all sorts of round and split woods: chestnut, black-wood, oak…

Wood peeling of diameters from 40 mm (1.6”) up to 150 mm. (6”)

Chips discharge blower with swivelling spout through 360°. Ideal for loading the chips into a trailer.

Self-supported post (if less longer than 1.00 m (39”)).

Very efficient due to a convex disc fitted with 6 adjustable blades.

Robopel Post Peelers

Automatic Driving Rollers Release Option

Technical characteristics

Minimum wood diameter …………………………… 40 mm (1.6”)

Maximum wood diameter ……………………………150 mm (6”)

Transport dimensions (L x W x H) …………………. 0.84 m x 1.62 m x 1.94 m (33” x 64” x 76.5”)

Work dimensions (L x W x H) ……………………… 0.84 m x 1.89 m x 1.94 m (33” x 74.5” x 76.5”)

Weight …………………………………………………175 Kg (385 lbs)

Disc speed ……………………………………………1 500 rpm

Number of blades ……………………………………. 6

Drive PTO Speed ……………………………………. 540 rpm

PTO Power required ………………………………… 20 HP

Coupling Tractor 3-point linkage …………………… Cat. n°2 with removable pins

Discharge of chips By the top with the spout

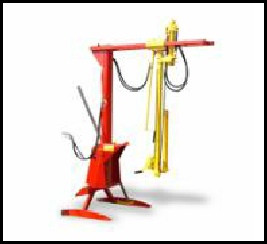

General characteristics of 3 Models: Biface 250A, Quadriface 250 & Biface 225

3 models adaptable on tractor 3-point linkage using PTO Driven Hydraulic Unit.

Points all sorts of posts (round or split) and all sorts of woods (chestnut, blac-wood, oak, pine...)

Biface 225 points up to 225 mm (8.85”)

Biface / Quadriface 250 up to 250 mm (10”) diameter.

Quick pointing of 2 sides of the post in the same time on the wood direction thanks to the 2 blades.

Points 4 sides in only one movement on QUADRIFACE 250 (4 blades).

Sharp Blades are made of hard-wearing steel.

Automatic blade start with the self-supported post (on BIFACE 225) Exclusive to RABAUD - Unique on the market.

Mechanical adjustment of the pointing angle (length) and of the final point section according to the post diameter.

BIFACE 250: Ergonomic machine with wide opening for an easy setting of the posts.

Safety of the blades supports.

|

Models |

Hydraulic post pointer BIFACE 225 |

Hydraulic post pointer BIFACE 250A |

Hydraulic post pointer QUADRIFACE 250 |

|

Maximum post diameter |

225 mm (8.85”) |

250 mm (10”) |

250 mm (10”) |

|

Blade starting |

Automatic with the post |

Mechanical with a pedal |

Electro-hydraulic with a pedal |

|

Dimensions without hydraulic unit (L x W x H) |

1.87m x 1.07m x 1.29m (74”x 42”x 51”) |

1.41m x 2.07m x 1.26m |

2.11m x 1.33m x 1.33m |

|

Dimensions with hydraulic unit (L x W x H) |

1.87m x 1.07m x 1.64m |

1.41m x 2.07m x 1.73m |

2.11m x 1.33m x 1.73m |

|

Weight without hydraulic unit |

330 kg |

455 kg |

635 kg |

|

Weight with hydraulic unit |

400 kg |

545 kg |

720 kg |

|

Drive |

Tractor pump 2 couplers or PTO 540rpm, 30L/min. |

Tractor pump 2 couplers or PTO 540rpm, 35L/min. |

|

|

Coupling |

Tractor 3-point linkage N°2 with removable pins |

||

|

Maximum output |

200 up to 250 posts / hr |

200 up to 250 posts / hr |

250 posts / hr |

Farm Tractor Mounted / Powered

Vibrating Post Driver : VIBROSCOPIC PRO

Vibrating Post Driver : VIBROSCOPIC II and III

Viticultural / Winery

Tractor Mounted

Vibrating Post Driver : VIBROSCOPIC 150

Vibrating Post Driver : VIBROSCOPIC II and III

General characteristics of Vibrating Post Driver on STRADDLE GRAPE HARVESTERS - Vibroscopic ll

Drives all types of posts in all types of grounds, thanks to the exclusive power regulation of the striking head by the operator.

Works in all positions: side shift, tilting, and rotation.

Excellent accuracy: the post is held during the work process.

Compact machine for transportation and for use (telescopic mast).

Does not damage the posts: power regulation of the striking head.

Control of the process from the driver's cabin and/or behind the machine, thanks to the electro-hydraulic control box.

Simple use: only one handle for lifting and lowering the hammer and for striking.

Incomparable safety: the hammer strikes only when the post is held under the head.

Sturdy striking head, wrought-iron, machined and treated, Ø 120 mm and/or 150 mm.

2-year warranty on striking head.

Adaptable to many

different vehicles

|

Model |

VIBRESCOPIC II |

|

Maximum post length |

User decision: According to the straddle grape harvester or tool carrier. |

|

Striking head diameter |

120 mm (4.75”) up to 150 mm (6”) |

|

Hammering |

Adjustable from 0 up to 950 strokes/min. |

|

Striking power under head |

Adjustable from 0 up to 230 joule/stroke (Equivalent, during one hour of continuous full power operation, to 828 Kilowatt Hours) |

|

Hydraulic side shift |

0.50 m (19.7”) (only on New-Holland Braud SB series) |

|

Mast hydraulic tilting Inner side - Outer side - |

20° 25° (20° on STILTOR) |

Option: Pre-holing Bar

With hydraulic extraction

General characteristics

Ideal for arboriculture and fruit-farming business for driving very long posts and stakes up to 4.60m (15 ft) max.

Ultra-powerful hammer (650 joule) especially designed for very long posts.

1.10m (43”) side shift on the striking head: ideal for driving post in already existing vegetation.

The tilting enables to drive post straight and/or putting tilted posts.

Total safety: vibrating hammer starts only when the post is in contact with the striking head.

Very low gravity centre: maximum stability at work or stored.

2-year warranty on striking head.

Vibrating Post Driver : VIBRESCOPIC 460 for Arboriculture & Related Businesses

Option:

Hydraulic Unit for 540 rpm PTO

Pump capacity 45 Ltr (11.8 US Gal) /min. Oil Tank capacity 60 Ltr (15.75 US Gal)

|

Model |

Vibrating Post Driver: VIBROSCOPIC 460 |

|

Post length (Min. / Max.) |

1.40 m (55”) / 4.60 m (15 ft) |

|

Ø mini. and maxi of posts |

80 mm (3.15”) / 150 mm (6”) |

|

Transport dimensions (L x W x H) |

1.40 m x 2.37 m x 3.99 m (4 ft 7” x 7 ft 9” x 13 ft 1”) |

|

Work dimensions (L x W x H) |

1.40 m x 2.73 m x 5.75 m (4 ft 7” x 8 ft 11.5” x 18 ft 10.5”) |

|

Weight |

1 400 kg (3080 lbs) |

|

Hammer power |

650 joules |

|

Offset |

1100 mm (43”) |

|

Side shift |

15° innner side / 10° outer side |

|

Coupling |

Tractor 3-point Category 2 |

Technical Characteristics

Technical Characteristics

Technical Characteristics

Vibrating Post Driver on MINI-EXCAVATOR

Vibrating Post-Driver adaptable onto Mini-Excavator, Backhoe loader... Etc.

The only effective equipment adaptable and made to measure for these types of carriers.

General characteristics

Adaptable on Mini-Excavator, or Backhoe loader.

RABAUD offers adaptations for automatic coupling or quick-fit coupling for all brands.

Drives posts of all types into all grounds without adjustment.

Excellent accuracy: The post is held during the work.

Simple to use.

Strongly-built striking head, wrought steel, machine-finished and processed, Ø 120 mm (4.75”) and/or 150 mm (6”).

2-year warranty striking head.

The advantages of the VIBROSCOPIC II 15/35:

- Ideal for mini-excavators from 1.5T up to 3.5T.

- Hammer mounted on square runner, anti- wearing and dis-mountable.

The advantages of the VIBROSCOPIC PRO 35/95:

- Lighter model thanks to the tension cylinder.

- More powerful hammer and higher hammering frequency.

- Wider striking head.

Adjustable power: Does not damage the posts.

Option:

Pre-hole bar extraction.

Barbed wire unwinding machine: CLOTURMATIC RXB

General characteristics

4 models for the fence-making from 2, 3, 4 or 5 strands in only 1 pass.

Unwinds and put up the barbed wire coils (500 m (547 Yds) long max.)

Even stretching of the barbed wire thanks to the stretching pinions and their separate disc brakes.

Perfect lining of the barbed wires against the post thanks to the 1.00 m (39.4”) hydraulic side shift.

Slope correctors +/- 30° for putting up the wire parallel to the posts.

Adjustable strand distance.

Staple air nailing pistol stainless steel or galvanised (option).

Loading platform for putting the barbed wire coils.

Road lighting kit.

Main Options:

- Air nailing pistol with compressor

- Slope corrector (inclination +/- 30°)

- Electro-mechanical time meter.

|

Models |

Barbed wire unwinding machine: 2 RXB |

Barbed wire unwinding machine: 3 RXB |

Barbed wire unwinding machine: 4 RXB |

Barbed wire unwinding machine: 5 RXB |

|

Number of unwinding Systems |

2 |

3 |

4 |

5 |

|

Dimensions without unwinding system (L x W x H) |

1.93 x 2.43 x 1.50m (7ft 4” x 8ft x 4ft 11”) |

1.93 x 2.43 x 1.50m (7ft 4” x 8ft x 4ft 11”) |

1.93 x 2.43 x 1.50m (7ft 4” x 8ft x 4ft 11”) |

1.93 x 2.43 x 1.50m (7ft 4” x 8ft x 4ft 11”) |

|

Dimensions with unwinding system (L x W x H) |

1.93 x 2.43 x 2.38m (7ft 4” x 8ft x 7ft 10”) |

1.93 x 2.43 x 2.38m (7ft 4” x 8ft x 7ft 10”) |

1.93 x 2.43 x 2.38m (7ft 4” x 8ft x 7ft 10”) |

1.93 x 2.43 x 2.38m (7ft 4” x 8ft x 7ft 10”) |

|

Weight |

950 Kg (2090 lbs) |

1 030 Kg (2266 lbs) |

1 110 Kg (2442 lbs) |

1 190 Kg (2618 lbs) |

|

Hydraulic side shift |

1.00 m (39.4”) |

1.00 m (39.4”) |

1.00 m (39.4”) |

1.00 m (39.4”) |

|

Drive |

Tractor pump with 2 hoses and 2 couplers or PTO 540rpm |

|||

|

Coupling |

Tractor automatic 3-point linkage with round bar Category N°2 |

|||

|

Electric supply |

12V electro-hydraulic control / 12V road lighting kit |

|||

Technical Characteristics

Wire netting unwinding machine: CLOTURMATIC GRX - & Combined with Brabed Wire Installation

General characteristics

Unwinds wire netting rolls from 0 up to 2.50 m (8ft 2.5”) high (on GRX 8025) and up to diameter 800 mm (31.5”), without risk for the user.

Possibility to unwind 1 or 2 strands of barbed wire on top of the netting.

Excellent tension of the netting: hydraulic stretching system of the wire netting controlled by the user from the driving cabin.

Stretching and holding grip during the nailing process or the linking of the netting rolls.

Loading platform for putting up the wire netting roll.

Staple air nailing pistol (option)

Wire netting always clean and put effortlessly. It is unwinded in vertical position.

Options: 2-way hydraulic valve, staple air nailing pistol, air compressor for the air nailing pistol, barbed wire unwinding system (2 max.)

Plain wire unwinding machine : DEROULMATIC

General characteristics

Adjustable frame: you can mount 1 up to 5 plates.

The machine is able to unwind 1 up to 5 plain wire coils in one pass.

The machine can wind 2 plain wire coils thanks to the option hydraulic winding system to mount on the plate (2 hydraulic winding systems max.).

The machine can be disassembled without tool and can be transported in a commercial trunk.

Adjustable coil diameter: thanks to 4 separate supports.

Easy coil extraction with the removable plates and the conical supports.

Stability with fixed support stands.

|

Model |

Plain wire undwinding machine DEROULMATIC |

|

Coupling |

Tractor 3-point linkage N°2 with adjustable blocks |

|

Drive |

Mechanical (Tractor pump 2 couplers for the winding system option) |

|

Winding options : Max. pressure Max. flow |

200 bar (2940 PSI) 50 L/min. (15 US Gal/min) |

|

Dimensions (L x W x H) |

1.61 m x 0.91 m x 1.60 m (5ft 3.5” x 3ft x 5ft 3”) |

|

Max. weight (5 rows + winding systems) |

290 Kg (638 lbs) |

Technical Characteristics

Hydraulic winding system

With 2 hoses and 2 couplers

To be mounted onto existing plate

Additional Coil Plate

| Accueil |

| Produit |

| About Us |

| Contact Us |

| Fuelwood |

| Rabaud |

| Quadivator |

| Fuelwood |

| Rabaud |

| Quadivator |